- Professional Construction Software Solutions

- 480-705-4241

Listening to LinkedIn Contacts

June 8, 2010Tagging LinkedIn Contacts

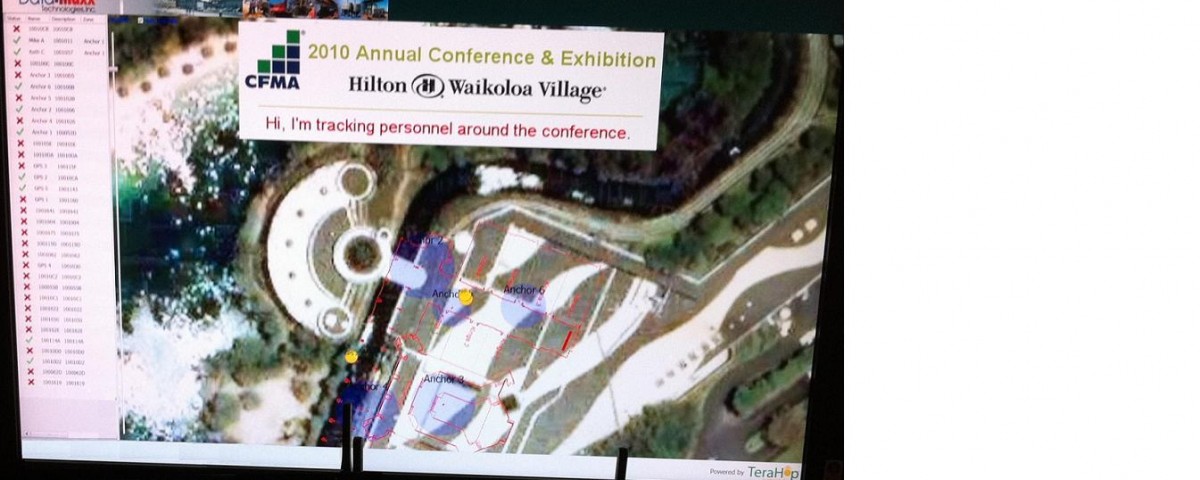

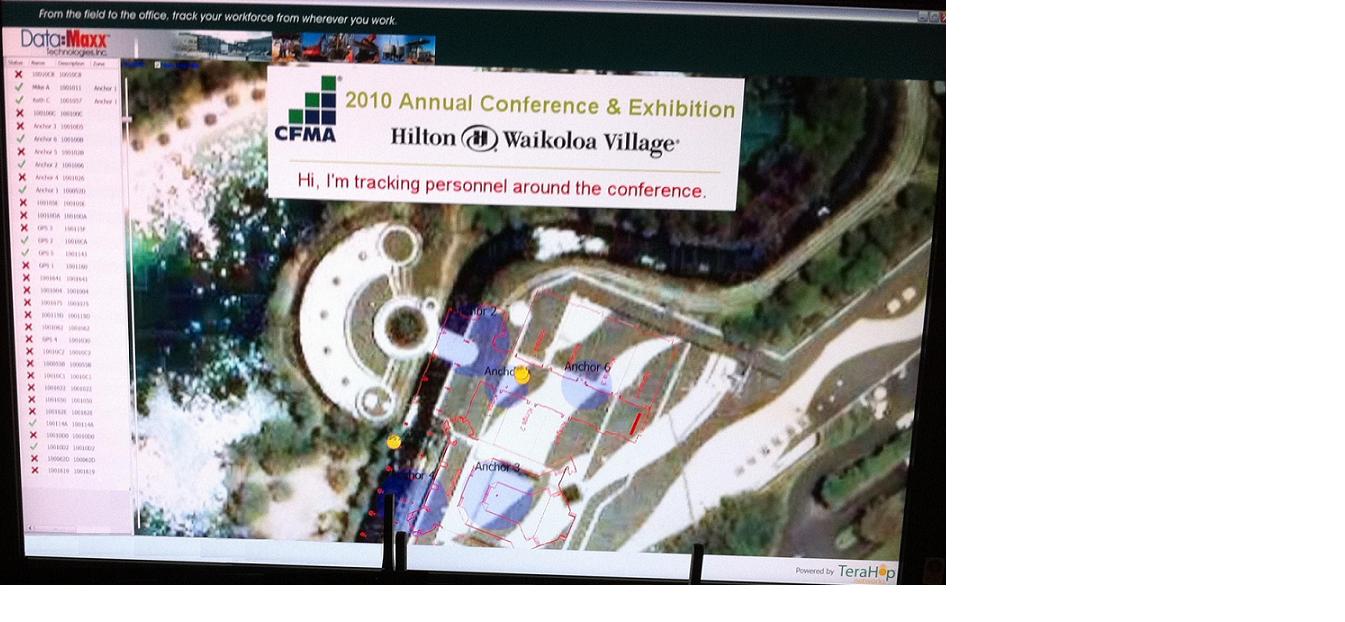

July 20, 2010Lean Construction has been a hot topic for the past few years and is still gaining momentum. Recently representatives of Mortenson spoke at a NAWIC Greater Phoenix Chapter meeting and discussed renewable energy (showcasing a wind farm project in Hawaii) and how lean construction practices have improved productivity and their bottom line. Since I just happened to attend the 2010 CFMA National Convention in Kona last week, I was able to see the wind mills in person. But I also had the opportunity to peruse the vendor exhibits at convention and found a tool that may solve multiple construction problems in one fell swoop…TeraHop.

TeraHop Networks Inc provides On-Site asset monitoring without using satellite or cellular subscriptions. They call their solution the Construction Asset Monitoring System or CAMS for short. With Portable Data Collectors (PDCs) acting as local sensors and network routers, they track the movement of assets and create hopping paths to other PDCs and directly with TeraHop’s Wireless Data Uplink (WDU). The WDU holds the collected data until it is able to upload to a server via wireless or ethernet interface. WDUs also have a GPS receiver to permit localization of PDCs in the network. The WDU generated information from the site-wide data can be viewed from a computer or smartphone at the site or any other location with a wireless connection. So what can they track? Equipment, vehicles, inventory, tools and personnel…basically anything that moves on your jobsite!

After talking with representatives it dawned on me that contractors using this technology are collecting information often gathered when beginning a lean evaluation. Tracking the steps of employees then asking why and what were you doing is one of the best ways to minimize waste and eliminate mistakes, the two mantras of LEAN. Since you can also redeploy you can revisit a jobsite after making lean improvements in task assignments that were to “save steps”, analyze the improvements and adjust again if necessary…a continuous improvement method in Lean. Now add this to the DataMaxx solution and you have streamlined, accurate time collection for payroll processing, inventory tracking and equipment run-time.

Since CAMS can monitor equipment and vehicles, the ability to reduce excessive engine idle time (which impacts fuel costs and equipment wear) is a common by-product from the collected data analysis. Knowing actual equipment run-time will help manage preventative maintenance schedules, eliminate too frequent or late maintenance, and decrease the cost of ownership. You can use this on the jobsite or in your yard to make your fleet managers job easier.

All these process improvements add up, make lean construction worthwhile and more profitable. If you’ve used the TeraHop system or something like it, I’d like you to share your experiences in the comments with my readers. If you think this is a good idea but have reservations, ask me questions. I’ll get TeraHop to respond quickly if I get stumped.

1 Comment

CAMS is one of the useful device that tracks your assets where it is located sitting at your office.